Summary

Additive: N-OR type HALS : RIASORB® UV-123

Application: Outdoor weathering protection for coatings

Key benefits: Low basicity | Higher light stabilization efficiency | Ease of Operation | Weathering and Long-Lasting Performance

The Challenge

Ultraviolet Absorbers (UVA) and Hindered Amine Light Stabilizers (HALS) are useful tools for coatings and other materials, to protect against outdoor weathering. While UVA can protect coatings by absorbing harmful UV rays. HALS will work in a synergistic way, via tripping free radicals generated in the early stage of degradation. Although HALS products are widely used as efficient light stabilizers, the basicity caused by amine groups may sometimes become a source of various troubles for formulating chemists. Additionally, selecting the right type and concentration of HALS is crucial to strike a balance between effective UV stabilization and any unwanted side effects.

The Solution

RIASORB® UV-123 is a liquid non-basic HALS. As the basicity of HALS is determined by the group linked to nitrogen atom in piperidine. Compare to the methyl group on RIASORB® UV-292, a general-purpose HALS. Alkoxy group (-OR) with stronger electron-withdrawing effect can endow RIASORB® UV-123 with lower basicity.

RIASORB® UV-123, a N-OR type HALS, has four outstanding advantages:

1. Low basicity , suitable for special coating systems

(1) Acid-catalyzed coating systems: When coatings need to use strong acid catalyst, or large amounts of acid catalysts, traditional basic HALS products such as RIASORB® UV-292 may neutralize with the acid catalysts, thus which can negatively affect the curing process. For example, strong catalysts such as T-PSA (p-toluene sulfonic acid) usually appear in systems where methylated amino resins are used as cross-linker.

Note: 5 drops of HALS added to 20mg/ml of T-PAS solution, RIASORB®UV-292 on the left, RIASORB® UV-123 on the right.

(2) Alkali-catalyzed coating systems: such as epoxy- acid systems, which will use organic amines as catalysts. The introduction of high-basic HALS may accelerate the cross-linking reaction of the coating during storage or transportation, thus reducing the stability. Therefore, the use of low basicity RIASORB®UV-123 is highly recommended for this type of system.

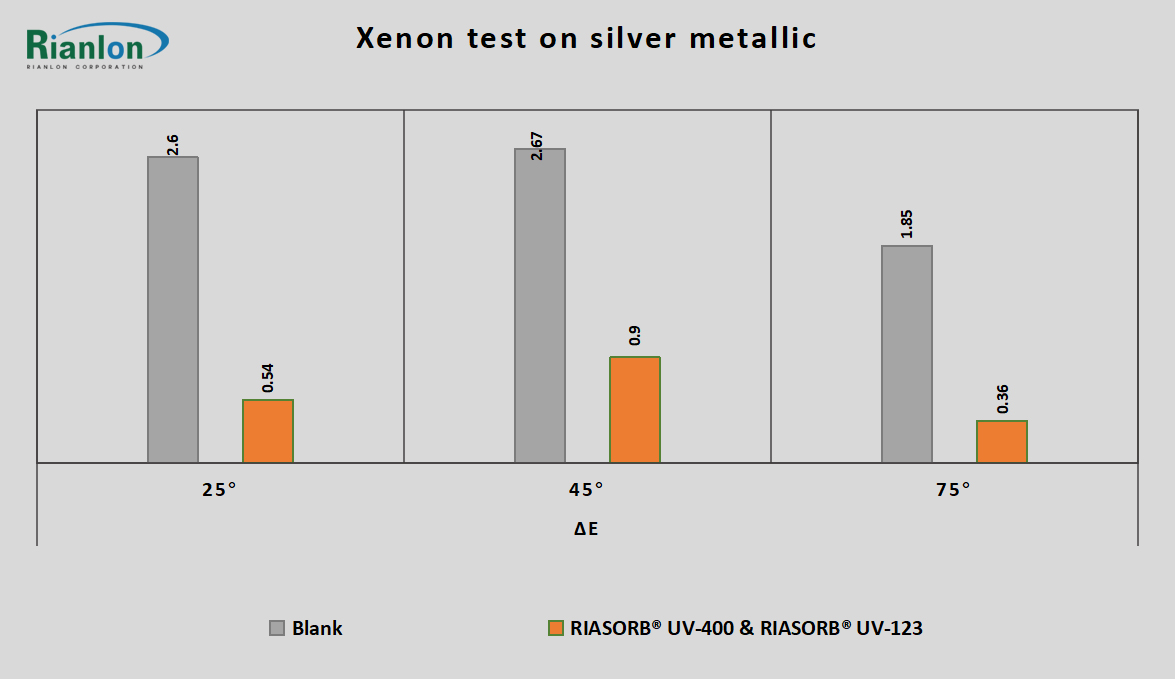

The following is the tested effect of RIASORB® UV-123 in an epoxy- acid clearcoat for automotive OEM application.

- A silver metallic basecoat with 1K epoxy-carboxylate clearcoat was used.

- The protected clearcoat contains 1.2% RIASORB® UV-400 and 0.6% RIASORB® UV-123, and the test panels were exposed in xenon weathering chamber according to SAE J-2527 (total irradiation is 4,500 KJ).

In addition, the low basicity prevents the production of dark colors by interacting with metal residues in the material. Or it reduces interactions with other acidic materials such as acidic pigments and acidic resins. For these special coating systems, such low basicity HALS is sometimes necessary.

2. Higher light stabilization efficiency

N-OR type HALS can rapidly convert into nitrogen-oxygen radicals (>NO-), which are the active species responsible for the light stabilizing effect. This property contributes to a very high light stabilization efficiency. In other words, this type of HALS is effective at preventing degradation due to light exposure, such as UV radiation.

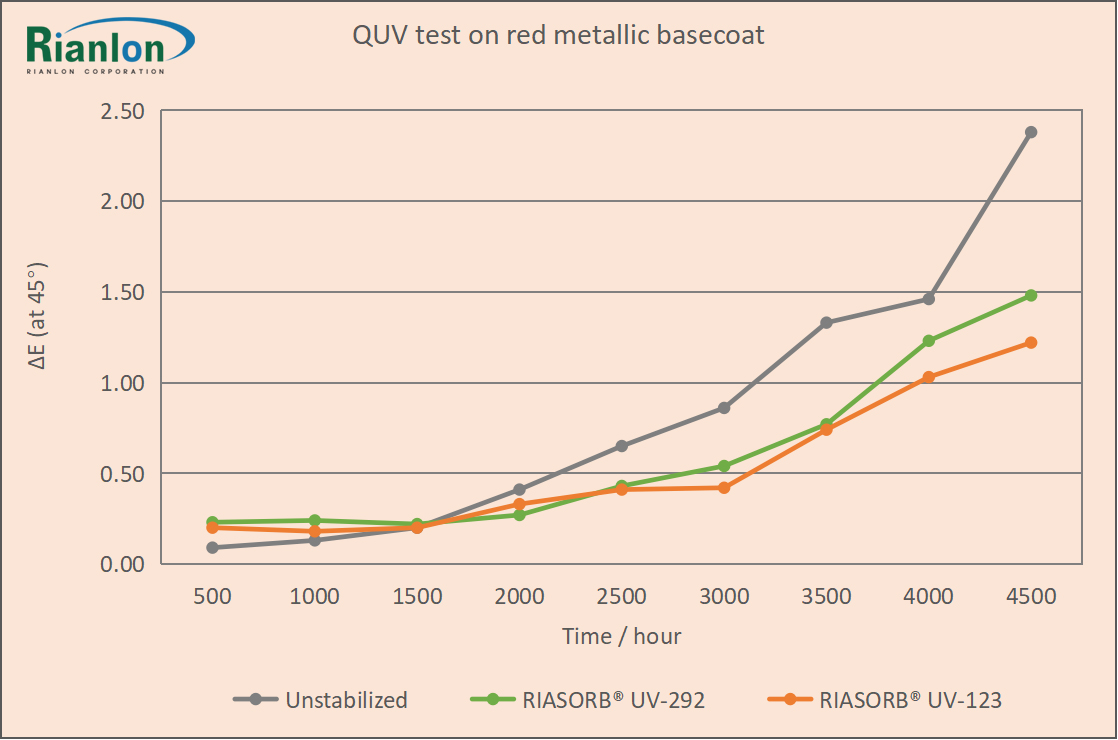

The following test results were performed on an automotive refinish, using a red metallic base coat with a 2K acrylic-polyurethane clear coat. The protected clearcoat contains 1.2% RIASORB® UV-928 and 0.6% HALS, and the test panels were exposed under QUV according to ASTM G-154-06, cycle 1 (340nm lamp)

In this test, it shows that RIASORB® UV-123 has better color retention than the conventional HALS product, RIASORB® UV-292, over a long period of protection.

3. Ease of Operation

The product is noted for its ease of use in formulations. This is important for formulating chemists, as it simplifies the process of incorporating the HALS into various coating systems. It implies that RIASORB® UV-123 can be integrated into a wide variety of complex formulations with minimal complications, saving time and effort during the formulation process.

4. Weathering and Long-Lasting Performance

RIASORB® UV-123 is also praised for its ability to deliver excellent weathering resistance. This means that it helps coatings withstand the effects of outdoor exposure, including UV radiation, temperature variations, and other environmental factors. Its long-lasting performance ensures that the coated materials maintain their appearance and functionality over an extended period.

Conclusion

RIASORB® UV-123, as a N-OR type HALS, appears to be a highly efficient light stabilizer that offers formulating chemists ease of operation while providing excellent weathering resistance. This makes it a promising choice for high-performance coatings and a noteworthy advancement in the field of light stabilization additives.

Rianlon is always with you along the road to green technology in the coatings industry.