From General Plastics to Engineering Plastics: Comprehensive Protection for Electronic and Electrical Materials

In the home appliance industry, polymers have become the second most widely used raw material after metals and are among the fastest-growing material categories in recent years. In addition to common general plastics such as PP, ABS, and PVC, appliances also utilize engineering plastics like ASA, PA, PC, POM, MPPO, PET, reinforced PBT, and PSF. As electronic and electrical products continue to evolve, the polymers used in both internal and external components are subject to increasingly stringent performance demands. Exposure to high temperatures, humidity, and electromagnetic radiation accelerates material aging, leading to degradation or even failure. Rianlon’s advanced anti-aging solutions safeguard the long-term stability of these products, enhancing reliability and extending service life.

One-Stop Solutions Across Applications

-

Living Room & Kitchen Appliances

-

Wires & Cables

-

Living Room & Kitchen Appliances

Living Room & Kitchen AppliancesApplications include mobile phones, computers, TVs, refrigerators, washing machines, air conditioners, dishwashers, robotic vacuum cleaners, power tools, and connectors.

-

Flexible Sealing & Soft-Touch Components

Flexible Sealing & Soft-Touch Components

TPE/TPV (e.g., electric pressure cooker seals, juicer non-slip pads); PVC (e.g., power cord jackets).

-

Outer Casing & Structural Components

-

Transparent/Optical Components

-

High-Temperature & Motion Components

-

Insulation & Flame-Retardant Components

-

UV Resistance

-

Heat Resistance

-

Anti-Discoloration

-

Anti-Degradation

-

Flexible Sealing & Soft-Touch Components

Flexible Sealing & Soft-Touch Components

TPE/TPV (e.g., electric pressure cooker seals, juicer non-slip pads); PVC (e.g., power cord jackets).

-

Outer Casing & Structural Components

-

Transparent/Optical Components

-

High-Temperature & Motion Components

-

Insulation & Flame-Retardant Components

-

-

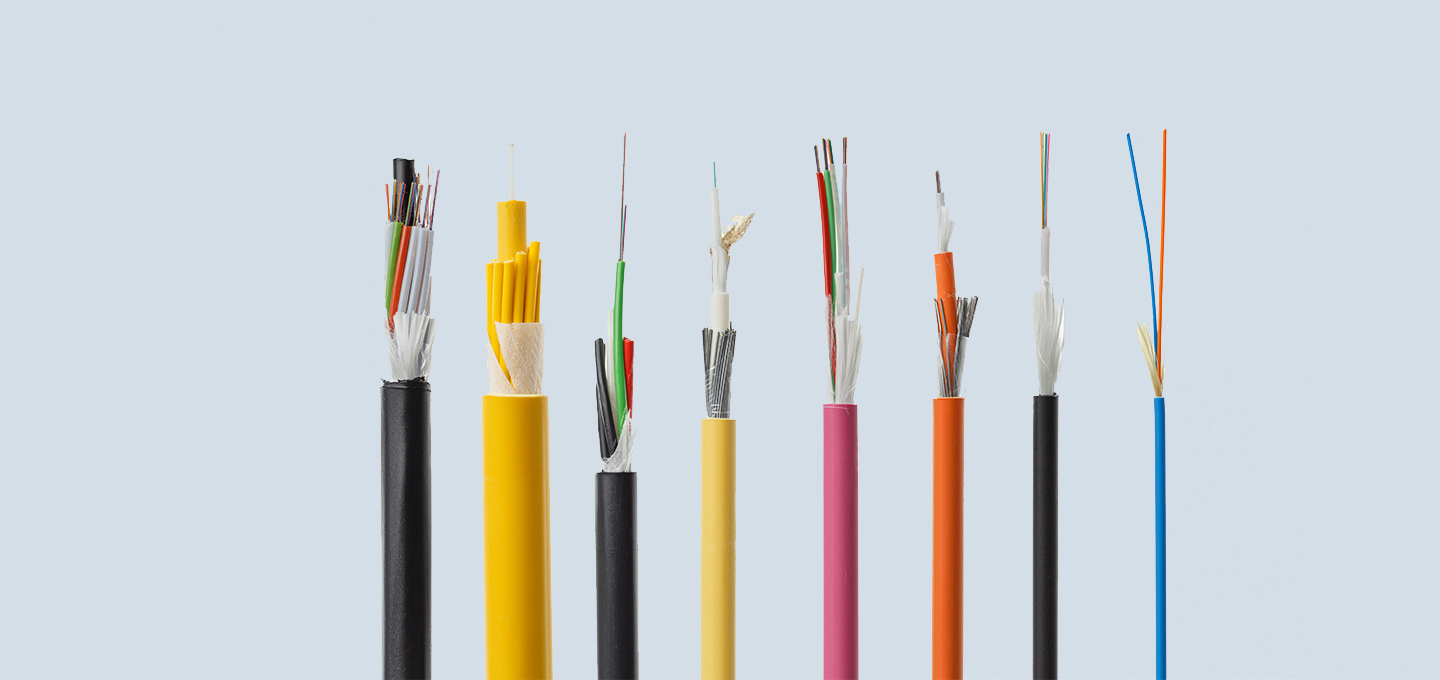

Wires & Cables

Wires & CablesCommunication Equipment

-

High-Temperature/Special Material Layers

High-Temperature/Special Material Layers

Rianlon's high-performance cable material solutions deliver exceptional thermal resistance and chemical stability, making them ideal for applications such as electric blanket wires, aerospace equipment, medical devices, and high-frequency signal cables (using materials such as SIR/PTFE).

-

Conductor Shielding Layer (for High-Voltage Cables)

Conductor Shielding Layer (for High-Voltage Cables)

Conductive PE/XLPE (medium/high-voltage power cables): Recommended antioxidants RIANOX® MD-1024, RIANOX® MD-697; EPR (marine and wind power cables).

-

Filling & Cushioning Materials

Filling & Cushioning Materials

Fillers for multi-core cables (e.g., PP ropes): Recommended antioxidants RIANOX® MD-1024, RIANOX® MD-697; insulation layers for TV signal cables (e.g., foamed PE): Recommended antioxidant RIANOX® 330

-

Sheath Layer

Sheath Layer

Rianlon's weather-resistant cable solutions provide long-term durability under heat, mechanical stress, and flame-retardant requirements. They are widely used in building wiring, subway tunnels, and mining cables ( PVC, LSZH, PUR ), and work synergistically with flame-retardant systems.

-

Insulation Layer

-

UV Resistance

-

Heat Resistance

-

Anti-Discoloration

-

Anti-Degradation

-

High-Temperature/Special Material Layers

High-Temperature/Special Material Layers

Rianlon's high-performance cable material solutions deliver exceptional thermal resistance and chemical stability, making them ideal for applications such as electric blanket wires, aerospace equipment, medical devices, and high-frequency signal cables (using materials such as SIR/PTFE).

-

Conductor Shielding Layer (for High-Voltage Cables)

Conductor Shielding Layer (for High-Voltage Cables)

Conductive PE/XLPE (medium/high-voltage power cables): Recommended antioxidants RIANOX® MD-1024, RIANOX® MD-697; EPR (marine and wind power cables).

-

Filling & Cushioning Materials

Filling & Cushioning Materials

Fillers for multi-core cables (e.g., PP ropes): Recommended antioxidants RIANOX® MD-1024, RIANOX® MD-697; insulation layers for TV signal cables (e.g., foamed PE): Recommended antioxidant RIANOX® 330

-

Sheath Layer

Sheath Layer

Rianlon's weather-resistant cable solutions provide long-term durability under heat, mechanical stress, and flame-retardant requirements. They are widely used in building wiring, subway tunnels, and mining cables ( PVC, LSZH, PUR ), and work synergistically with flame-retardant systems.

-

Insulation Layer

-

Solution Advantages

-

Excellent Thermal Stability

Excellent Thermal StabilityExtends the service life of products such as wires and cables, electric heater grilles, iron housings, rice cooker shells, and air conditioner vents under high temperatures.

-

Long-term photo-oxidative aging resistance

Long-term photo-oxidative aging resistanceEnhances the weather resistance of materials like air conditioner outdoor unit housings, heater vents, and vacuum cleaner shells, ensuring stable appearance and performance over prolonged use.

-

One-Stop Solutions

One-Stop SolutionsProvides comprehensive anti-aging solutions covering products, technology, and services, based on a full range of antioxidants and light stabilizers.

-

Extensive Industry Experience

Extensive Industry ExperienceWith nearly 30 years of expertise in polymer anti-aging, we serve more than 30 specialized sub-industries, delivering proven and reliable solutions tailored to diverse challenges.

Recommended Products

We offer a full range of anti-aging additives to enhance material performance and support green development.

-

Primary Antioxidants

-

Secondary Antioxidants

-

UV Absorbers

-

HALS

-

U-pack

-

RIANOX® 245

RIANOX® 245Asymmetric hindered phenolic primary antioxidant.

Learn More -

RIANOX® 1098

RIANOX® 1098Especially Apply to hindered phenolic primary antioxidant of polyamides.

Learn More -

RIANOX® MD-697

RIANOX® MD-697A metal polymer deactivator containing a hindered phenolic structure

Learn More -

RIANOX® MD-1024

RIANOX® MD-1024A metal polymer deactivator containing a hindered phenolic structure

Learn More -

RIANOX® 1076

RIANOX® 1076A widely used hindered phenolic main antioxidant.

Learn More -

RIANOX® 1010

RIANOX® 1010Most widely used hindered primary antioxidant.

Learn More

-

RIANOX® 412S

RIANOX® 412SA thioester secondary antioxidant with excellent performance

Learn More -

RIANOX® DLTP

RIANOX® DLTPThioesters Secondary antioxidants

Learn More -

RIANOX® DSTP

RIANOX® DSTPThioesters secondary antioxidants

Learn More -

RIANOX® 686

RIANOX® 686Phosphite ester with excellent performance as a secondary antioxidant.

Learn More -

RIANOX® 626

RIANOX® 626Highly effective phosphite - secondary antioxidant

Learn More -

RIANOX® 168

RIANOX® 168Most widely used Phosphite ester antioxidant.

Learn More

-

RIASORB® UV-531

RIASORB® UV-531Benzophenone ultraviolet absorbent

Learn More -

RIASORB® UV-326

RIASORB® UV-326A benzotriazole type ultraviolet absorber that has the effect of absorbing longer wavelength ultraviolet light

Learn More -

RIASORB® UV-329

RIASORB® UV-329Widely used as benzotriazole ultraviolet absorbent.

Learn More -

RIASORB® UV-360

RIASORB® UV-360Very low volatility benzotriazole ultraviolet absorbent

Learn More -

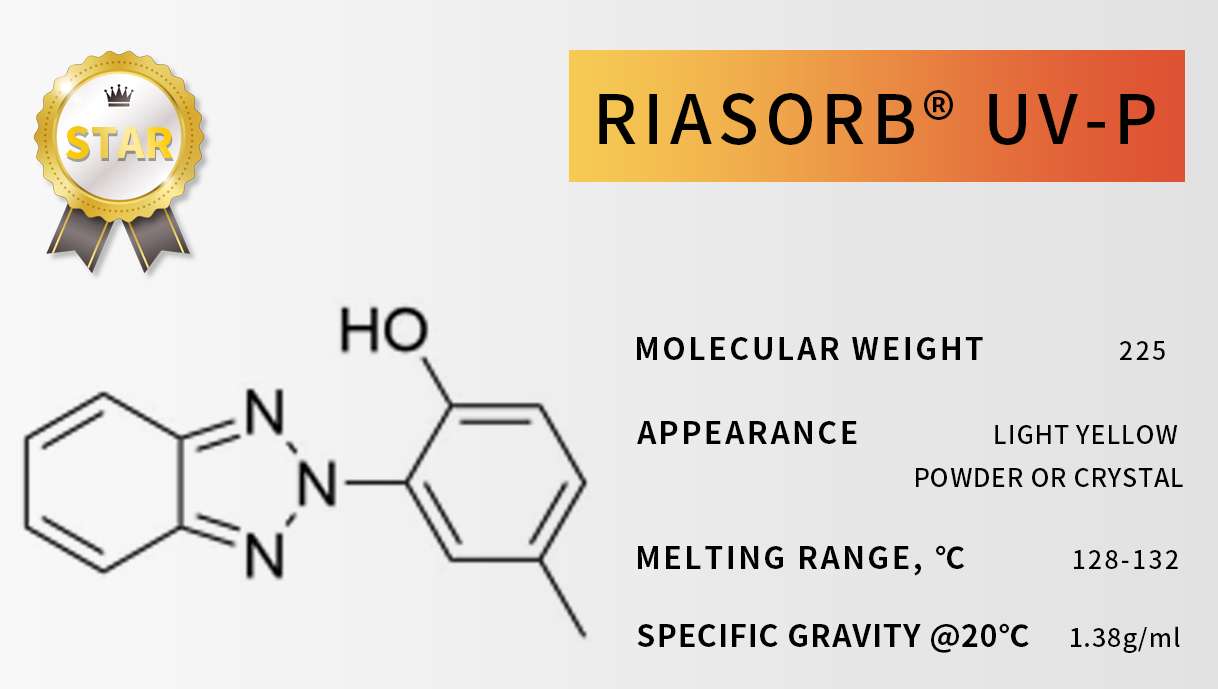

RIASORB® UV-P

RIASORB® UV-PWidely used as benzotriazole ultraviolet absorbent

Learn More -

RIASORB® UV-234

RIASORB® UV-234Low volatility benzotriazole ultraviolet absorbent.

Learn More -

RIASORB® UV-1577

RIASORB® UV-1577Low volatility, good compatibility with the material of o-hydroxyphenyltriazine UV absorbers, compared with phenyltriazolium UV absorbers can significantly improve the weatherability of materials

Learn More -

RIASORB® UV-1164

RIASORB® UV-1164Low volatility, good compatibility with the material of o-hydroxyphenyltriazine UV absorbers, compared with phenyltriazolium UV absorbers can significantly improve the weatherability of materials.

Learn More

-

RIASORB® UV-119S

RIASORB® UV-119SHighly effective hindered amine light stabilizer.

Learn More -

RIASORB® UV-2020

RIASORB® UV-2020Block Oligomeric Hindered Amine Light Stabilizer

Learn More -

RIASORB® UV-944

RIASORB® UV-944A widely used polymerized hindered amine light stabilizer.

Learn More -

RIASORB® UV-770DF

RIASORB® UV-770DFA widely used low molecular weight hindered amine light stabilizer.

Learn More -

RIASORB® UV-622

RIASORB® UV-622A polymerized hinderer amine light stabilizer

Learn More

-

U-pack® UV-7308

U-pack® UV-7308U-pack light stabilizer masterbatch for PP automotive materials.

Learn More -

U-pack® UV-7303

U-pack® UV-7303U-pack light stabilizer masterbatch for PP automotive materials.

Learn More -

U-pack® B7327

U-pack® B7327Antioxidant U-pack:The master-batch for PP compounding in automotive industry

Learn More -

U-pack® UV-783

U-pack® UV-783Used in polyolefin industry.

Learn More -

U-pack® B215

U-pack® B215General antioxidant U-pack.

Learn More -

U-pack® B225

U-pack® B225General antioxidant U-pack.

Learn More